RADIATORS

M.O.C

Volute Casing ,Black Plate ,Impell are in Polypropylene /

PVDFSalient Features

Pumps are available in different mounting constructions like horizontal bare pumps, monoblock pump. Pump shaft & sleeves are available with different materials compatible with the liquid handled.

Application

- Bare shaft polypropylene pump used for continuous process operation.

- Monoblock pump can be used for transfer application (intermittent use)

- Vertical pumps for lifting corrosive lying at the bottoms tanks.

- Sealless glandless pumps used for handling effluent water.

Polypropylene can handle more than 560 types of chemicals Like Ammonium Chloride I Pickling, Con. HCL Acid, Calcium Sulphate, Caustic Soda, Cynic Acid, Ferric Nitrate, Phosphoric Acid and many more

| Capacity Range | Up to 100 Ms3/hr |

| Head Range | Up to 63 Mtr |

| Electrical Motor | Up to 25 HP |

Salient Features

- Volute & Impellers are injection molded PVDF material with smooth hydraulic passage.

- Shaft are available with sleeves of different materials compatible with the liquid handfed

- Pumps are available with externally mounted balanced mech seal or teflon gland packing or Internal mech seal with elastomer bellows.

- Less space required & easy to handle

- Excellent mechanical properties over a wide range of temperature (23°C to 130° C) . Abrasion resistance comparable to that of Polyamide, and relatively low coefficient of friction.

- Smooth running and long service life of the mechanical seal.

- Epoxy paint to protect from external protection of pump.

- External cooling arrangement provided in pump for enhancement of mechanical seal life.

Polypropylene can handle more than 560 types of chemicals Like Ammonium Chloride I Pickling, Con. HCL Acid, Calcium Sulphate, Caustic Soda, Cynic Acid, Ferric Nitrate, Phosphoric Acid and many more Liquid Handled

Polypropylene can handle more than 560 types of chemicals Like Ammonium Chloride I Pickling, Con. HCL Acid, Calcium Sulphate, Caustic Soda, Cynic Acid, Ferric Nitrate, Phosphoric Acid and many more

| Capacity | upto 190m3/hr |

| Head | upto 51 meters |

| Power | upto 55HP |

| Max liquid temp | 130°C |

| Max working pressure | 7kg/cm2 |

| RPM | 2900/1440 |

| Solid % | Max 30% |

| Solid Size | Max 3mm |

Sealing Arrangement Carbon / SIC

MOC

- Volute Casing, Open Turbine type Impeller & back plate is made from SS-316 investment casting.

Salient Features

Self Priming.

Application

Wide range of applications in various industries such as alimentary, petro-chemical, Textile, Pharmaceutical, Depuration. For pumping inflammable liquids with flame proof motors.

Liquid Handled

Barium Cyanide, Barium Sulphate, Carbon Di Sulphate, Hexane, Hydrogen Fluoride Platting Sol. Copper & iron and Many More

| Capacity Range | 7 LPM to 183 LPM |

| Head Range | 2 to 70 Mtr |

| Electrical Motor | 0.5 HP to 3.0 HP |

MOC

- All pumps parts and impellers are in SS-316

Salient Features

- Good finishing

- Silent operation

- Back pull out design

- Extremely compact

- Easy to install.

Application

- Food products

- Chemical Solutions

- Industrial Liquids

- Petrochemicals

- Electroplating Solutions

- Pharmaceuticals.

Liquid Handled

DM Water, Milk, Juice, etc. and many more.

| Capacity Range | 40 LPM to 900 LPM |

| Head Range | 9 to 72 Mtr |

| Electrical Motor | 1/2 Hp to 20 Hp |

| Sealing Arrangement | Carbon / SIC ,SIC / SIC, TC / TC |

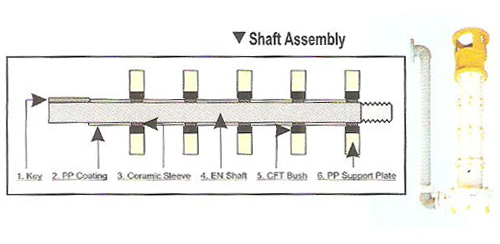

- Moniba vertical PP Pump is designed with multipal bearing support. MOC of bearing bush is CFT (Carbon filled teflon) & shaft sleeve is ceramic

- Due to multi support of bearing bush, maintenance / breakdown the is reduce in multifolds.

- Due to multi support of bearing bush, vertical pump can be operated at high speed i.e. 2900 rpm, hence lesser hp friOilDf. (Power saving)

- Moniba has developed inhouse technology to fabricate a shaft sleeve in ceramics between two pp coating on shaft

- Multi support over comes the problem of shaft vibration & imbalance.

APPLICABLE INDUSTRIES

- Automotive Industry

- Cosmetics

- Paints & Coatings

- Shipbuilding

- Beverage Industry

- Food

- Pharmaceutical Industry

- Textile & Carpet

- Ceramics

- Furniture Industry

- Plating

- Water and Sewage Treatment

- Chemical Industry

- Mining

- Refineries

- Utility

- Construction Industry

- Municipalities

- Road Tanker Truck

- Petrol / Gas Stations

SALIENT FEATURES

- No seal, No leakage

- No motor, No fire. Explosion proof

- No rotation, No charging, less wear and tear.

- Self priming, No foot valve needed.

- Pump can run dry without damage

- Variable flow, with same pump

- Stop automatic on closing of discharge valve..

- Can be submerged.

- Light weight, handy in use.

- Can handle solids 2mm to 10 mm.

- Less stock of spare parts to be maintained.

- No skilled person is needed to operater or repair pump

- Also can be used as metering pump up to accuracy of 3 - 5%

- In short a very simple and versatile pump.

SPECIFICATIONS

This Parameters depend on size of pump

| Temperature | Max 90°C |

| Solid Size | Max 10 MM |

| Solid % | Max 50% |

| Viscosity | 15000 CP |

| Self Priming | 6Mtr of water column |

| Model | Inlet air connection in inches | Inlet in inch | Outlet in inch | Max Flow in LPM | Max Solid Size in MM | Material of casing |

| AIRON15 | 1/4" | 1/2 | 1/2 | 33 | 2.5 | PP,SS,PVDF,AL |

| AIRON25 | 1/4" | 1 | 1 | 60 | 3.4 | PP,SS,AL,PVDF |

| AIRON40 | 1/2" | 1.5 | 1.5 | 140 | 5.0 | PP,SS,AL, |

| AIRON50 | 3/4" | 2 | 2 | 300 | 6.5 | PP,SS,AL |

| AIRON80 | 1" | 3 | 3 | 440 | 10.0 | ALUMINUM |